Woodworking Machinery

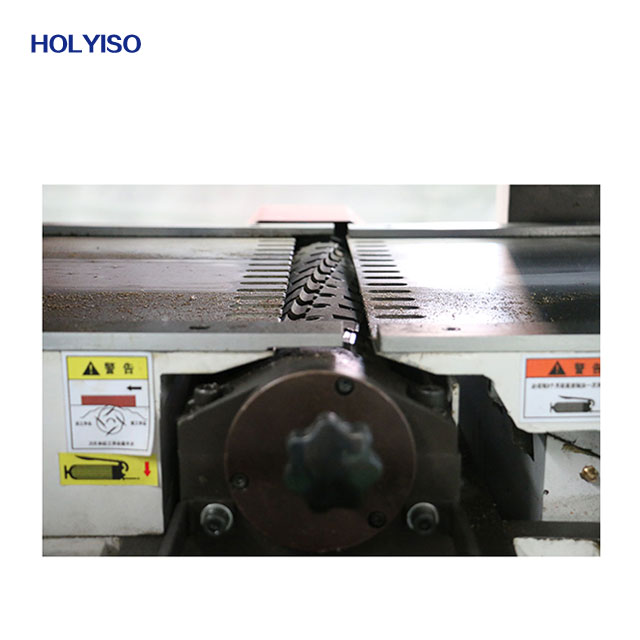

MB206H Heavy Duty Double Sides Planer with helical cutter

MB206H Heavy Duty Double Sides Planer &nb

MB206H Heavy Duty Double Sides Planer

with helical cutter

Technical Parameters:

Max. working width | 25-610mm |

Max. working thickness | 10-180mm |

Min. working length | 260mm |

Max. cutting depth (upper spindle) | 4mm |

Max. cutting depth (bottom spindle) | 4mm |

Cutting Tool Spindle diameter | 100mm |

Knife Nos.on Top cutter head | 90pcs |

Knife Nos.on Bottom cutter head | 90pcs |

Knife Sizes | TCT30X12X1.5mm |

Cutting Spindle speed | 4800r/min |

Feeding speed | 3-20m/min |

Upper spindle motor power | 11kw(15HP) |

Bottom spindle motor | 5.5kw(7.5HP) |

Feeding motor power | 2.2kw/3.7kw(Frequency Control) |

Lifting motor power | 0.37kw |

Total motor power | 21.07kw/22.57kw |

Dust Exit Diameter | 150mm |

Voltage | 380V |

Overall size | 2500x1200x1750mm |

Packing size | 2600x1300x1850mm |

Net weight | 3500kg |

Applications:

Processing of single-side, double sides for sets of furniture, all kinds of woodiness material and laminated wood.

Features:

1.The feeding unit can be adjusted upwards and downwards, the elevating range reaches 10mm, so the processing precision can be enhanced with powerful feeding.

2.With driven feeding roller structure, ensuring a stronger and smoother feeding. Also it is equipped with overloading protection mechanism.

3.The main parts such as machine frame and workable etc. are made from aged Cast iron and precisely machined, having the features of high accuracy and good vibration absorption.

4.Equipped with pressure plate which guarantees short workpiece can be smoothly machined, increasing production output.

5.Special speeding adjustment device combining with power torque worm reducer which enables it to select feeding speed according to actual requirement.

6.Equipped with imported digital display device. Operation is convenient and the working accuracy is up to 0.01mm. Also feeding speed can be shown.